Bonyane Bongata ba Odara:100 lik'hilograma

Lintlha tsa Pakete:

Paka A: 16kg / Metal Barrel

Phakete B:24KG Plastiki Barrel

Paka C: E ipapisitse le palo ea moemeli oa B A

Nako ea thomello:Matsatsi a leshome ka mor'a ho fumana tefo ea pele

Matla a Phepelo:Lithane tse 2 ka Letsatsi

Mmala:Silevera

PH:3.8-5.2

Matla a Khoheli a khethehileng:1.30±0.05

Viscosity:20~60s(Spray Coating) 60~90S(Dip-Spin Coating)

Cr6+:≥25g/L

Tlhaloso

JH-9392 e entsoe ka liphutheloana tse tharo: A,B le C;

Pakete ea A: Ke silevera e bohlooho slurry eo haholo-holo e kopantsoeng ka lik'hemik'hale le flake e ntle haholo ea Zn, flake e ntle haholo Al le ethylene glycol.Karolelano ea radius-botenya ba Zn plate ke 60 ~ 100.

Pakete ea B: Ke mokelikeli oa seaparo se nang le 'mala o mofubelu oa lamunu le tharollo ea metsi, e nang le Cr6 +.

Pack C: Ke sebono sa ho roala se entsoeng haholo-holo ka selulose e tšoeu kapa phofo e mosehla.

Ho fokotsa mafura

Mosebetsi o lokela ho tlosoa haeba ho na le oli holim'a metsi.Ho na le mekhoa e meraro ea ts'ebetso:

1.Mocheso o phahameng;

2.Neutral metsi-base degreasing agent;

3.Organic solvent joalo ka methylene chloride.

Derusting

The workpiece e ke ke ea tlotsoa haeba ho na le mafome kapa burr holim'a metsi.Mokhoa o motle ka ho fetisisa oa ho sebetsa ke ho thunngoa ho phatloha.Ho hanyetsa kutu ea ho roala ho tla etsoa haeba ho hloekisoa ha acid ho amoheloa.

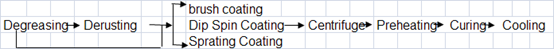

Ho roala

The workpiece afer degreasing and shot blasting e lokela ho koaheloa ka Dip-Spin coating kapa Spraying Coating.

Ho futhumatsa pele

The workpiece ka mor'a hore a tlosoe e lokela ho ba Pre-heated kapele kamoo ho ka khonehang ho 80 ~ 150 ℃ bakeng sa 8 ~ 15 mins ho fetoha mouoane.(ho ea ka ho monya mocheso oa workpiece.)

Ho phekola

Mosebetsi ka mor'a ho futhumatsa pele o lokela ho phekoloa ka 300-340 ℃ bakeng sa 20-40 mins.(ho ea ka ho monya mocheso oa workpiece.)

Ho paka

Paka A: 16kg / Metal Barrel

Phakete B: 24KG Plastic Barrel

Paka C: 5.0kg tšepe barrel

Nako ea tiiso ea boleng

Pele ho motsoako likhoeli tse 6 ho 20 ℃

Kamora matsatsi a 40 ho 20 ℃ (E ka sebelisoa hape haeba o ntse o eketsa koae e ncha khafetsa.)

E lokela ho bolokoa ka tlas'a 20 ℃ haeba e sa sebelisoe.

Mokhoa oa ho roala

Kopanya Karolelano

Paka A: 16.0 lik'hilograma

Sephutheloana sa B: 24.0 kg (boima bo ka eketsoa ka nepo haeba ho tlotsoe ka spray)

Paka C: 0-50 g (ho ea ka tlhokahalo e fapaneng ea viscosity)

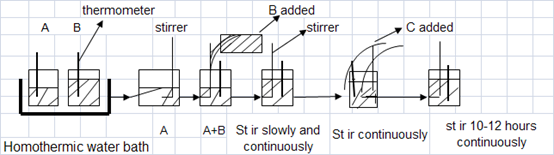

Mokhoa oa Motsoako

Pele ho Motsoako, Boloka A&B e boima ka bateng ea metsi ka 25 ± 2 ℃, ebe o hlohlelletsa A ho etsa hore tšepe e seretse e qhalane ka mokhoa o ts'oanang ka motsoako oa maqhubu, kamora hore A e qhalane ka ho lekana, fokotsa lebelo le sisinyehang ho 60r/min, ebe o eketsa B.

Kenya B ho e susumetsang A butle-butle.Hajoale, mocheso oa moqomo o tla nyoloha, ha o fihla ho 35 ℃, ho qala sesebelisoa sa sehatsetsing ho boloka mocheso oa moqomo o sa fetohe ho 35 ℃.

Hlohlelletsa motsoako ka lihora tse ka bang 1 ~ 2 ka potlako ka mor'a hore B e kenyelelitsoe, ebe u eketsa C. C e lokela ho ba phofo haeba ho na le lesela. ka mehla.

Ho roala ho lokela ho sefshoa ka skrine ea tšepe e sa hloekang ea 80 ~ 100 mesh pele e tšeloa ka har'a moqomo oa ho qoela.

Sesebediswa sa taolo ya mocheso se lokela ho ba le dip barrel ho boloka mocheso wa ho roala o le 22 ±2℃.

(Haeba mocheso o phahame haholo, pente e ka senyeha, 'me viscosity e tla etsoa.) Ho roala ho lokela ho tsosoa ka selika-likoe ho boloka ho hasana ka ho lekana.

Boima ba liteko, PH, Thempereichara, Viscosity le Cr6+ litaba tsa ho koahela lihora tse ling le tse ling tse 8 haeba li sebetsa khafetsa.

Kopanya setšoantšo

Tlhokomelo

Lik'hemik'hale tse ling tse kang mefuta efe kapa efe ea asiti, letsoai la alkali ha le khone ho kopanngoa le ho roala, hobane tsena li ka etsa hore Zn & Al plate e tsofale.

Qoba mahlaseli a letsatsi le mahlaseli a ultraviolet nako e telele ha o sebetsa, ho seng joalo e tla potlakisa botsofali kapa polymerization ea ho roala.

Ho bohlokoa haholo ho laola mocheso oa ho roala.Haeba mocheso oa ho roala o fetoha ha o sebetsa, o tla etsa hore ho be le viscosity, ebe o etsa hore boleng ba ho roala bo sebetse holim'a workpiece.Kahoo likamano pakeng tsa mocheso, viscosity le mokhoa oa ho ohla li lokela ho laoloa hantle ha ho roala.

Viscosity e tla fapana haeba mokhoa oa ho roala o fapane.Khetha lintlha tse tlase haeba u fafatsa, 'me u khethe lintlha tse phahameng haeba u li roala.

Lintlha tsa Tekheniki

| Che. | Ntho | Lintlha |

| 1 | PH | 3.8-5.2 |

| 2 | Cr6+ | ≥25g/L |

| 3 | Matla a khoheli a khethehileng | 1.30±0.05 |

| 4 | Viscosity | 20 ~ 60s (Spray Coating);60~90S(Dip-Spin Coating) .20 ℃ Zahn 2 # senoelo |

| 5 | Mocheso oa ho sebetsa | 22±2℃ |