Bonyane Bongata ba Odara:500 lik'hilograma

Lintlha tsa Pakete:1000kg / barrel

Nako ea thomello:Matsatsi a leshome ka mor'a ho fumana tefo ea pele

Matla a Phepelo:Lithane tse 2 ka Letsatsi

Mmala:Mokelikeli o se nang Mebala ho ea ho o mosehla

Boima bo itseng:1.00-1.10

PH:13.0-14.0

Alkalinity ea Mahala (piont):≥20

Ho paka:1000kg / barrel

Nako ea ho sebetsa:Selemo se le seng

Tlhaloso

1. e khutšoanyane

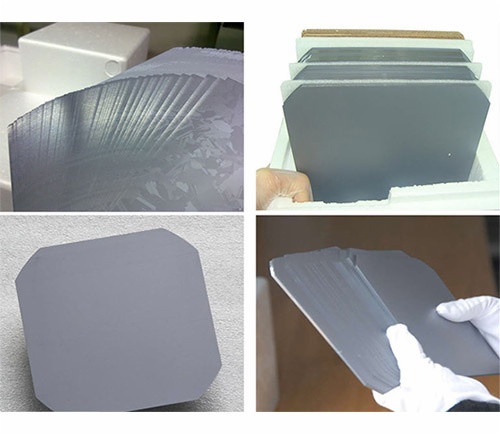

Lihlahisoa tsa Junhe Type-1017 ke lihlahisoa tse nang le karolo e le 'ngoe tse kopantsoeng haholo le letsoai la potasiamo, corrosion inhibitor, complexant, detergent le surfactant ka polymerization.The reagent grade potassium hydroxide e fana ka saponification alkalinity.Polymerization corrosion inhibitor, complexant, detergent le surfactant li fana ka tlhoekiso.Sehlahisoa sena se na le ts'ebetso e ntle haholo ho emulsifying, saponification le ho hloekisa oli ea liphoofolo, oli ea meroho, oli ea diminerale, ho emisoa le peista ea ho sila.E na le phello e matla ea ho hlobolisa, ho rarahana le ho hloekisa li-ion tsa tšepe.Ho hloekisoa ha oli ke 99% e le ho lemoha.Ho hlobolisa, ho kopanya le ho hloekisa phello ea koporo, tšepe le li-ion tse ling tsa tšepe.Ho sa le joalo, lihlahisoa tsa Junhe Type-1017 ha li na phosphate, calcium, magnesium, iron, copper, lead le li-ion tse ling tse kotsi tsa silicon tsa tšepe 'me li finyella litlhoko tsa EU ROHS tse nang le tšireletso e ntle ea tikoloho le bokhoni bo matla ba ho hloekisa.

2. tšobotsi

1) Lihlahisoa tsa Junhe Type-1017 ke lihlahisoa tse phahameng tsa karolo e le 'ngoe tse ka eketsoang khafetsa ka pompo ea othomathike moleng oa othomathike.

2) Ha e na phosphorus mme e finyella litlhoko tsa tšireletso ea tikoloho ea EU ROHS.

3) Ke mofuta oa sehlahisoa se tlaase sa foam 'me se ka sebelisoa moleng oa ho fafatsa le ultrasonic ntle le foam e phallang.

4) Lintho tsa ion tsa tšepe ha li fete 50PPm ntle le potasiamo le sodium ion 'me li ka finyella tlhokahalo ea IT ea ho nepahala ho phahameng.

5) ts'ebetso e ntle ea degreasing ho fihlela tlhokahalo ea sebaka sa IT se nepahetseng haholo.

3. sebelisa taeo

1) eketsa metsi a hloekileng a 3/4 ka tanka ea ho hloekisa pele.

2) haeba u e sebelisa moleng oa tataiso, ho khothaletsoa ho eketsa 5 ~ 10 kg ea Junhe Type-1016 silicon chip cleanse agent ka mokelikeli oa tanka ea 1000.Ha u hloekisa le ho sila peista silicon chip le silicon chip sehiloeng ka ho fanyeha ho hlaphoheloa, o lokela ho eketsa litekanyetso tse ling nakong ea lihora tse 8 tsa ho fetoha ho latela litlhaloso tsa k'hamphani ka 'ngoe.Ha e le hantle, fokotsa litekanyetso ha u boloka lihlahisoa tsa silicon chip.

3) Haeba o eketsa ka mokhoa o tsoelang pele moleng oa othomathike, bula tanka e nang le 1 ~ 2 kg Junhe Type-1017 silicon chip cleaning agent ka mokelikeli oa tanka ea 100 'me u laole ho eketsa ho tsoelang pele ho latela tekanyo ea ho hloekisa silicon chip.Bakeng sa ts'ebetso e ntle ea ho hloekisa, ho khothalletsoa ho fetola lichifi tse 1 ~ 3.

4) Ka kakaretso kilogram e 'ngoe ea Junhe Type-1017 silicon chip cleanse agent e ka hloekisa li-silicon chips tse fetang 1000 tsa 125 # monocrystal silicon chips.Eketsa ho latela karolo ena.Ha u hloekisa ho belisoa le ho sila ho peista silicon chip le silicon chip cut with recovery suspension, should add more doses.Ha e le hantle, fokotsa litekanyetso ha u boloka lihlahisoa tsa silicon chip.

5) Ebe u eketsa metsi a hloekileng ho fihlela boemo ba ts'ebetso le mocheso ho mocheso o hlokahalang ebe o ka o sebelisa.

6) Silicon chip e lokela ho pepesoa ka seoelo kamoo ho ka khonehang nakong ea ho hloekisa e le ho thibela ho hlahisa likarolo tsa lipalesa.

4. lintlha

1) Molamu oa kristale o ke ke oa koloba ka mor'a ho itšeha ka mela.Haeba e ke ke ea hloekisoa ka nako, ho tla ba molemo hore e kenngoe ka har'a sesebelisoa sa ho fanyeha kapa ho hloekisa (ho qoelisoa ka ho feletseng)

2) Hang ha molamu oa kristale ka mor'a hore ho itšeha ka mela e hloekisitsoe, e lokela ho sebetsanoa hang-hang.Ha e lumelloe ho etsa hore silicon chip e omelle ka tlhaho nakong ea ho hloekisa.

3) E tlameha ho boloka silicon chip e kolobile ha e degumming mme ha ea lokela ho etsa hore e ome ka tlhaho.

4) Koala sesebelisoa sa foaming ha ultrasonic hloekisa tanka 1 le 2. ka mor'a ho ba lishelefong, bula foaming 'me haholo-holo qoba moloko oa fragment.

5) ka mor'a hore potoloho e 'ngoe le e' ngoe ea ho hloekisa e phethoe (joalo ka phetoho ea lichelete), fetola litanka tsa metsi tse hloekileng tsa tanka ea 5, tanka ea 6, tanka ea 7 le tanka ea 8 ka botlalo.

6) Basebeletsi ba hloekisang ba ke ke ba tšoara chip ea silicon nakong ea ho hloekisa 'me ba tlameha ho roala liatlana tsa rabara haeba ho ka hatisoa menoana.

7) E le ho boloka bohloeki ba silicon chip, nako ea ho hloekisa ho fafatsa pele ho degumming e lokela ho laoloa ka hare ho metsotso e fetang 30.

8) Haeba ho na le mathata a kang chip e litšila le mollo nakong ea ho sebelisoa, ka kopo ikopanye le basebeletsi ba tšebeletso ea theknoloji ka nako.

9) Ha u ntša sehlahisoa, se hloka neutralization, flocculation le sedimentation le ts'ebetso e 'ngoe e bonolo.Sehlahisoa ha se na tšepe e boima le orthophosphate.

Lintlha tsa Tekheniki

| Ponahalo | Seedi se se nang mmala ho isa ho bosehla |

| Boima bo itseng | 1.00-1.10 |

| PH | 13.0-14.0 |

| Mahala alkalinity(piont) | ≥20mg |